Tooling Design: Customized Solutions by XYZ Engineering

At XYZ Engineering, we understand that tooling design is a crucial element in optimizing industrial processes and improving operational efficiency. Our specialized approach to design allows us to offer custom solutions that meet the unique needs of each client. From conceptual design to final implementation, we are committed to delivering products that not only meet the highest standards but also add significant value to your operations.

Types of Tools

At XYZ Engineering, we offer a wide range of tooling design solutions across various industrial sectors. Below, we describe some of the most common types of tooling design that we provide:

1. Handling Tool Design

Handling tools are designed to facilitate the handling of components and products during the manufacturing process. These tools can include cranes, grippers, and lifting systems that ensure safe and efficient handling. Our design approach focuses on ergonomics and safety, ensuring that each tool is tailored to the specific needs of the process and improves overall productivity.

This piece-turning tool is designed to facilitate the safe and efficient handling of parts in industrial environments. Ideal for operations that require precise turning and positioning of heavy components, this equipment improves ergonomics and optimizes workflow. With its robust construction and advanced control system, it ensures safe and effective handling, reducing operation time and boosting productivity.

2. Molds and Templates Design

Mold and template design is crucial for the mass production of precise components. Molds enable the creation of parts with specific shapes and dimensions, while templates help guide processes like cutting, drilling, or assembly. At XYZ Engineering, we use cutting-edge technology for mold and template design, ensuring that each component is produced with maximum precision and consistency.

3. Assembly Tools Design

Assembly tooling design includes the creation of tools and devices that facilitate the assembly of components and products. These tools can be manual or automatic and are designed to reduce assembly time and minimize the risk of errors. Our team of tooling design experts works closely with clients to develop solutions that optimize the assembly process and improve operational efficiency.

4. Quality Control Tooling Design

Quality control tooling is essential to ensure that products meet quality standards and specifications. These tools can include measuring devices, testing equipment, and inspection systems that help identify and correct defects early in the production process. At XYZ Engineering, our approach to tooling design for quality control focuses on precision and reliability, ensuring that every product meets the required quality standards.

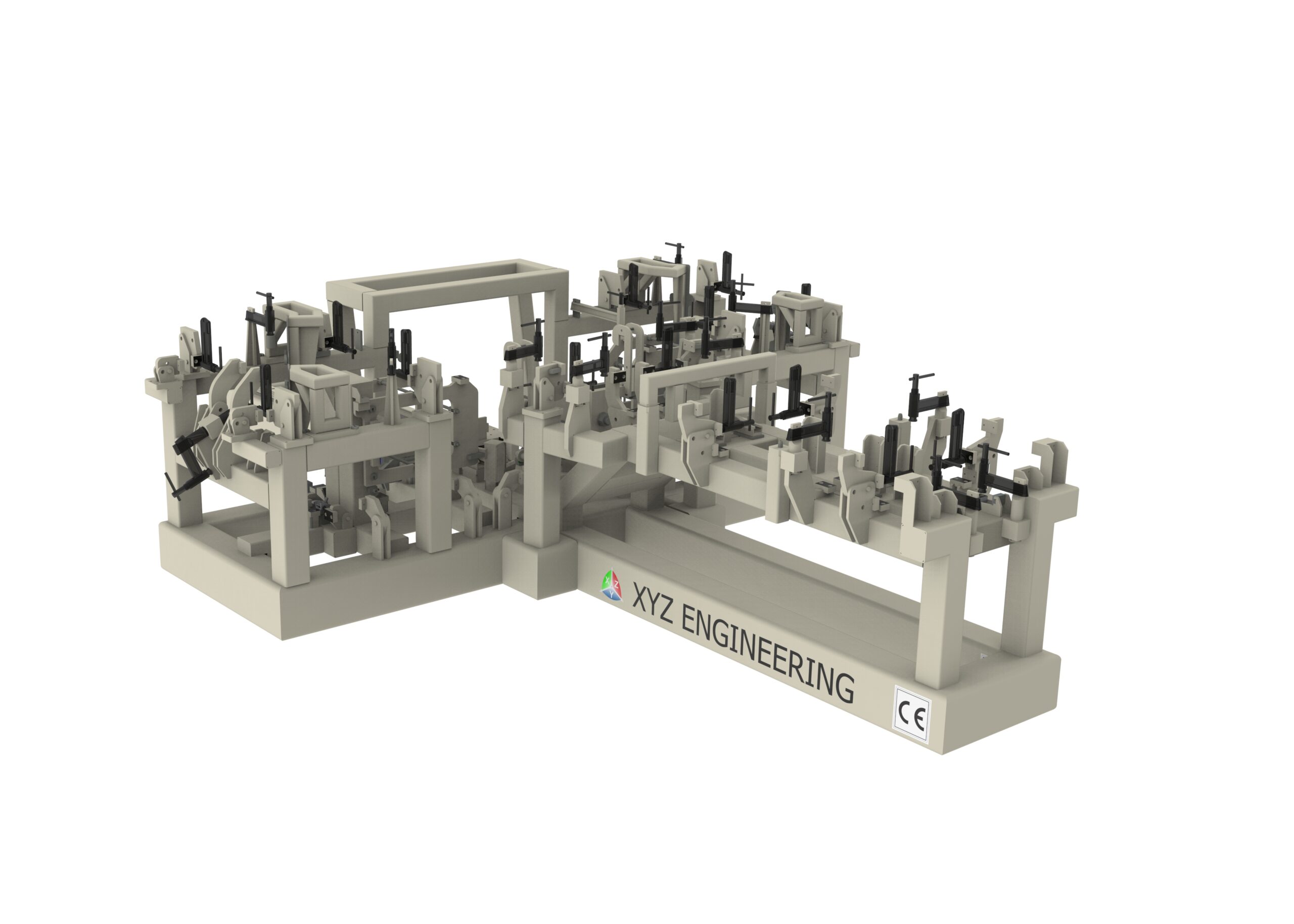

Image of tooling design for pillar B control.

Tooling Design Process at XYZ Engineering

1. Requirements Analysis

The first step in tooling design is a thorough analysis of the client’s requirements. This includes understanding the specific needs of the process, project objectives, and technical and operational constraints. This phase is crucial to ensure that the tooling design aligns with the client’s expectations and project requirements.

2. Concept Development

Once the requirements are defined, our team of engineers develops preliminary concepts for the tooling design. These concepts include sketches and 3D models that represent potential solutions. The concept development phase allows us to evaluate different approaches and select the best option for the project.

3. Detailed Design

The next step is the detailed design of the tooling. In this phase, we create precise technical drawings and specifications that guide the fabrication of the tooling. We use advanced Computer-Aided Design (CAD) tools to ensure that every detail is accounted for and that the tooling design meets quality standards.

4. Manufacturing and Testing

Once the design is approved, we proceed with manufacturing the tooling. During this phase, testing and adjustments are made to ensure that the tooling functions as intended. Our team conducts thorough quality control checks to ensure that the tooling design meets all specifications and client requirements.

5. Implementation and Support

Finally, the tooling is implemented in the client’s production environment. We offer continuous support to ensure that the tooling operates correctly and to address any issues that may arise. Our goal is to provide a complete and effective solution that enhances production efficiency and quality.

Conclusion

At XYZ Engineering, we are committed to offering exceptional tooling design solutions that meet the unique needs of each client. Our experience and focus on quality enable us to provide tooling that optimizes industrial processes and improves operational efficiency. If you are looking for a reliable partner for tooling design, don’t hesitate to contact us. We are here to help you find the perfect solution for your needs.

Contact Us